- Отправить по электронной почте : David@tmaxcn.com

- Отправить по электронной почте : Davidtmaxcn@gmail.com

- : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

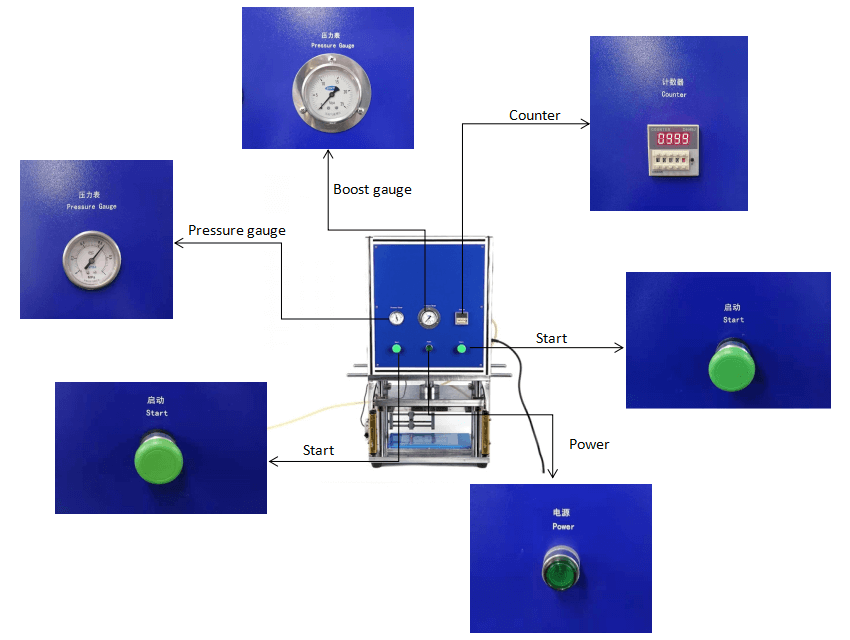

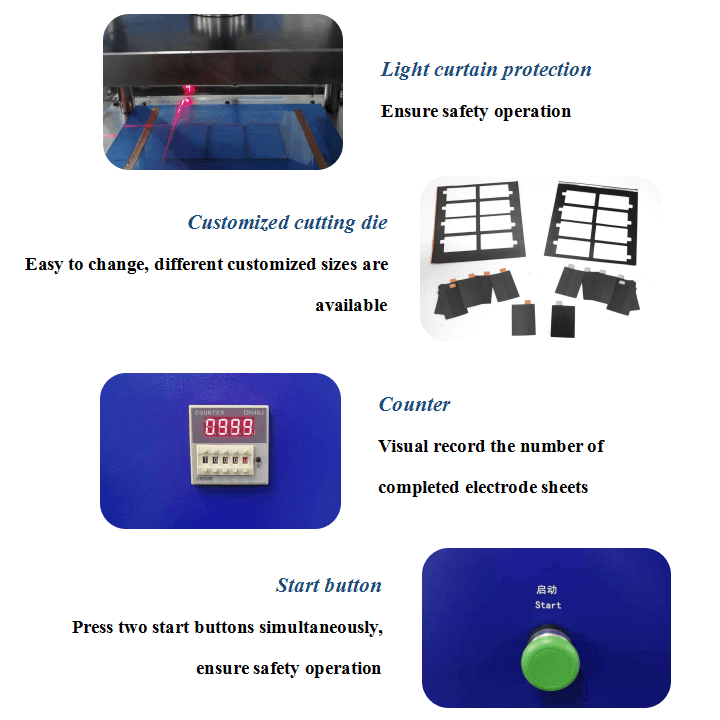

After being slurry coated, dried and pressed, the battery electrode of the carp ion battery forms a three-layer composite structure of fluid collector and two side coatings. Then, according to the design structure and specification of the battery, we need to cut the electrode sheet again. Generally, for the winding battery, the electrode sheet is divided according to the design width; The stacking battery and the electrode sheet are cut into pieces accordingly. At present, the cutting process of lithium ion battery electrode sheet mainly adopts the following two methods: (1) die punching, (2) laser cutting.

The metal die of pouch cell die cutter is used for punching die cutting machine, and the electrode sheet is cut by using the very small gap between the punch and the lower knife die. The coating particles are connected together by the adhesive. During the punching process, the coating particles peel off under the effect of stress, and the metal foil has plastic strain. After reaching the fracture strength, cracks occur, and the cracks grow and separate. The cross section of metal material blanking parts is divided into four parts: angle collapse, shear zone, fracture zone and burr. The wider the shear band of the section, the smaller the collapse angle and the burr height, and the higher the section quality of the punching part.The machine used for pouch cell assembly plant.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com