- Отправить по электронной почте : David@tmaxcn.com

- Отправить по электронной почте : Davidtmaxcn@gmail.com

- : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

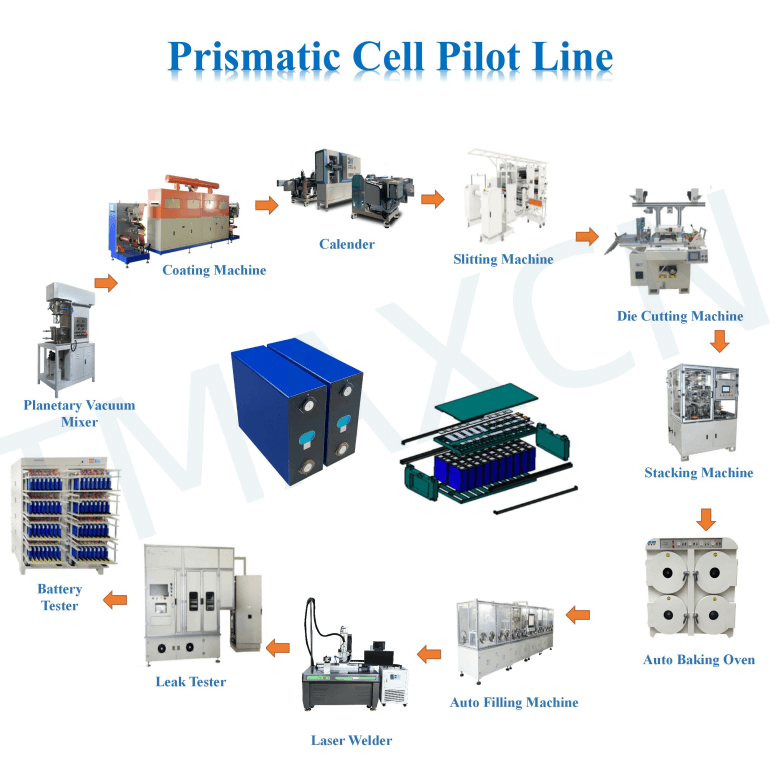

The EV car battery pilot line serves several crucial technical applications and offers numerous advantages in the development and production of electric vehicle battery pilot line:

1. Research and Development (R&D):

Technical Application: In the R&D phase, the pilot line allows researchers to explore and experiment with various aspects of battery technology. This includes investigating new materials, cell designs, and manufacturing processes. Researchers may explore lithium-ion, solid-state, or other emerging battery technologies.

Advantages: The pilot line facilitates the rapid testing of new concepts and materials, accelerating innovation. Researchers can fine-tune parameters and address challenges in a controlled environment.

2. Performance Testing:

Technical Application: EV car battery production line conducts exhaustive performance testing. This involves evaluating the battery's energy density, charging and discharging efficiency, thermal behavior, and its ability to handle different loads and environmental conditions.

Advantages: Detailed performance data generated in the pilot line helps optimize the battery's design, ensuring it meets or surpasses industry benchmarks for reliability and safety.

3. Quality Control and Standards Development:

Technical Application: Pilot lines play a crucial role in establishing quality control processes for battery manufacturing. They also contribute to the development of industry standards for battery safety and performance.

Advantages: Strict quality control ensures consistent battery quality, which is essential for safety and customer satisfaction. Developing industry standards contributes to the overall safety of electric vehicles.

4. Small-Scale Production:

Technical Application: Pilot lines are capable of producing limited quantities of battery packs. These packs can be used for small-scale EV testing, prototypes, or to supply specific niche markets.

Advantages: Small-scale production allows for real-world testing and validation in actual EVs. It helps identify any issues before full-scale production, saving time and resources.

5. Scaling Up Production:

Technical Application: Once a battery design has been validated and optimized on the pilot line, it can be smoothly transitioned to larger-scale manufacturing facilities.

Advantages: This ensures a seamless transition from research to mass production, minimizing disruptions and production challenges.

6. Customization and Flexibility:

Technical Application: Pilot lines can be tailored to suit different battery chemistries, sizes, and configurations based on specific research or production requirements.

Advantages: Flexibility allows for exploration of various battery options and customization for different EV models, ensuring compatibility and efficiency.

7. Collaboration and Innovation:

Technical Application: Pilot lines often serve as collaborative spaces where battery manufacturers, automakers, research institutions, and government agencies collaborate on cutting-edge battery projects.

Advantages: Collaboration fosters a rich exchange of ideas, accelerates innovation, and leverages collective expertise to solve complex battery-related challenges.

In summary, the EV car battery pilot line is a multifaceted facility that plays a pivotal role in advancing battery technology for electric vehicles. It serves as a hub for research, testing, and development, contributing to safer, more efficient, and longer-lasting EV batteries that drive the growth and sustainability of the electric vehicle industry.

ru

ru English

English

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com