- Отправить по электронной почте : David@tmaxcn.com

- Отправить по электронной почте : Davidtmaxcn@gmail.com

- : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

блог

Pouch Cell Making Machine

April 18,2025.

Pouch Cell Making Machine: The Key to Efficient Battery Production

A pouch cell making machine is a specialized piece of equipment designed to automate the manufacturing process of lithium-ion pouch cells. These machines play a critical role in ensuring high-quality, consistent production while addressing the unique challenges associated with flexible pouch cell design. In this blog post, we’ll delve into what a pouch cell making machine is, its components, how it works, and why it’s essential for modern battery manufacturing.

---

●What Is a Pouch Cell Making Machine?

A pouch cell making machine is an automated or semi-automated system that handles the entire process of assembling lithium-ion batteries enclosed in flexible aluminum-plastic laminate pouches. This machine integrates multiple stages of production, from electrode stacking to final sealing, ensuring precision, efficiency, and scalability in pouch cell manufacturing.

---

●Key Components of a Pouch Cell Making Machine

A typical pouch cell making machine consists of several integrated modules, each responsible for a specific stage of the assembly process:

1. Electrode Cutting and Coating Module

- Function: Cuts and coats cathode and anode materials onto metal foils (aluminum for cathodes, copper for anodes).

- Features: High-precision cutting tools and coating systems ensure uniform thickness and alignment.

2. Stacking/Winding Module

- Function: Stacks or winds the electrodes and separators together to form the core assembly.

- Types:

- Stacking: Used for flat pouch cells where electrodes are layered sequentially.

- Winding: Less common in pouch cells but used for jelly-roll configurations.

3. Pouch Insertion Module

- Function: Places the electrode assembly into the pre-cut aluminum-plastic laminate pouch.

- Features: Automated insertion mechanisms ensure accurate positioning without damaging delicate components.

4. Sealing Module

- Function: Seals three sides of the pouch to create an open enclosure for electrolyte injection.

- Features: Advanced sealing technologies like heat sealing or ultrasonic welding ensure airtight integrity.

5. Electrolyte Injection System

- Function: Injects liquid electrolyte into the pouch through the open side.

- Features: Precise control over injection volume and pressure to prevent overfilling or underfilling.

6. Final Sealing Station

- Function: Seals the fourth side of the pouch after electrolyte injection.

- Features: Ensures complete hermetic sealing to protect internal components from external contaminants.

7. Formation and Testing Module

- Function: Conducts formation cycles to activate the electrochemical properties of the cell and performs quality tests.

- Tests: Capacity, internal resistance, leakage, swelling, and short-circuit detection.

---

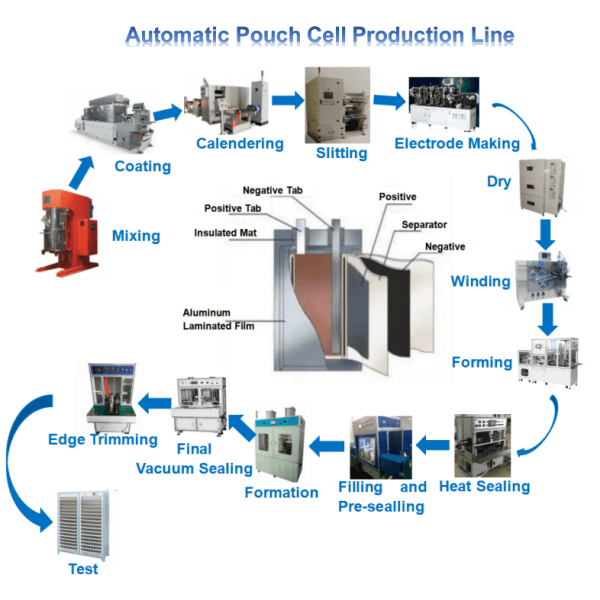

●How Does a Pouch Cell Making Machine Work?

The operation of a pouch cell making machine involves a series of coordinated steps:

1. Material Preparation

- Cathode and anode slurries are prepared and coated onto metal foils.

- Electrodes are cut into precise dimensions based on the desired cell size.

2. Stacking/Winding

- Electrodes and separators are stacked or wound together to form the core assembly.

3. Pouch Insertion

- The electrode assembly is carefully placed inside the aluminum-plastic laminate pouch.

4. Initial Sealing

- Three sides of the pouch are sealed using heat or ultrasonic welding techniques.

5. Electrolyte Injection

- Liquid electrolyte is injected into the pouch through the open side.

6. Final Sealing

- The fourth side of the pouch is sealed to create an airtight enclosure.

7. Formation and Testing

- Cells undergo formation cycles to activate their electrochemical properties and are tested for quality assurance.

---

●Advantages of Using a Pouch Cell Making Machine

1. High Precision:

- Automated systems ensure consistent alignment, stacking, and sealing, reducing defects and improving product quality.

2. Increased Efficiency:

- Automation speeds up production, enabling manufacturers to meet growing demand for pouch cells.

3. Cost Savings:

- Reduces labor costs and minimizes material waste through precise handling and processing.

4. Scalability:

- Can be configured for small-scale prototyping or large-scale mass production, depending on the application.

5. Improved Safety:

- Minimizes human exposure to hazardous materials like electrolytes and ensures safer working conditions.

Battery Production Line

●Challenges in Pouch Cell Making Machines

While pouch cell making machines offer numerous benefits, they also present certain challenges:

1. Complexity:

- The integration of multiple modules requires advanced engineering and software control systems.

2. Swelling Management:

- Ensuring minimal swelling during electrolyte injection and subsequent cycling remains a technical hurdle.

3. Sealing Integrity:

- Achieving reliable seals that withstand repeated charge-discharge cycles is critical but challenging.

4. Maintenance Requirements:

- Regular calibration and maintenance are necessary to maintain optimal performance and avoid downtime.

---

●Innovations in Pouch Cell Making Machines

To address these challenges and enhance productivity, manufacturers are incorporating cutting-edge technologies into pouch cell making machines:

1. Advanced Sensors and Vision Systems:

- Real-time monitoring of electrode alignment, sealing quality, and electrolyte levels ensures consistent output.

2. AI and Machine Learning:

- Predictive analytics optimize machine performance, detect anomalies, and improve yield rates.

3. Modular Design:

- Flexible machine configurations allow easy adaptation to different cell sizes and chemistries.

4. Sustainability Features:

- Eco-friendly designs minimize energy consumption and material waste during production.

---

●Applications of Pouch Cell Making Machines

Pouch cell making machines are widely used across industries requiring lightweight, high-energy-density batteries:

1. Consumer Electronics

- Smartphones, tablets, laptops, and wearables benefit from the compact and customizable nature of pouch cells.

2. Electric Vehicles (EVs)

- Many EV manufacturers rely on pouch cells for their superior energy density and space optimization.

3. Energy Storage Systems

- Residential and commercial energy storage solutions increasingly adopt pouch cells for scalability and efficiency.

4. Aerospace and Defense

- Lightweight pouch cells power drones, satellites, and other aerospace applications demanding high-performance energy storage.

---

●The Future of Pouch Cell Making Machines

As the demand for advanced batteries grows, pouch cell making machines will continue to evolve. Key trends shaping the future include:

1. Integration with Solid-State Technologies:

- Machines will adapt to handle solid-state electrolytes, enabling safer and more efficient next-generation batteries.

2. Higher Throughput:

- Advances in automation and robotics will further boost production speeds without compromising quality.

3. Customization Options:

- Modular designs will allow manufacturers to tailor machines for specific cell types and chemistries.

4. Sustainable Manufacturing:

- Recycling capabilities and eco-friendly processes will become integral parts of future making machines.

---

●Conclusion

Pouch cell making machines are indispensable tools in modern battery manufacturing, driving innovation and efficiency in the production of lightweight, high-performance pouch cells. As advancements in materials science, automation, and sustainability continue to unfold, these machines will play an increasingly important role in shaping the future of energy storage.

A pouch cell making machine is a specialized piece of equipment designed to automate the manufacturing process of lithium-ion pouch cells. These machines play a critical role in ensuring high-quality, consistent production while addressing the unique challenges associated with flexible pouch cell design. In this blog post, we’ll delve into what a pouch cell making machine is, its components, how it works, and why it’s essential for modern battery manufacturing.

---

●What Is a Pouch Cell Making Machine?

A pouch cell making machine is an automated or semi-automated system that handles the entire process of assembling lithium-ion batteries enclosed in flexible aluminum-plastic laminate pouches. This machine integrates multiple stages of production, from electrode stacking to final sealing, ensuring precision, efficiency, and scalability in pouch cell manufacturing.

---

●Key Components of a Pouch Cell Making Machine

A typical pouch cell making machine consists of several integrated modules, each responsible for a specific stage of the assembly process:

1. Electrode Cutting and Coating Module

- Function: Cuts and coats cathode and anode materials onto metal foils (aluminum for cathodes, copper for anodes).

- Features: High-precision cutting tools and coating systems ensure uniform thickness and alignment.

2. Stacking/Winding Module

- Function: Stacks or winds the electrodes and separators together to form the core assembly.

- Types:

- Stacking: Used for flat pouch cells where electrodes are layered sequentially.

- Winding: Less common in pouch cells but used for jelly-roll configurations.

3. Pouch Insertion Module

- Function: Places the electrode assembly into the pre-cut aluminum-plastic laminate pouch.

- Features: Automated insertion mechanisms ensure accurate positioning without damaging delicate components.

4. Sealing Module

- Function: Seals three sides of the pouch to create an open enclosure for electrolyte injection.

- Features: Advanced sealing technologies like heat sealing or ultrasonic welding ensure airtight integrity.

5. Electrolyte Injection System

- Function: Injects liquid electrolyte into the pouch through the open side.

- Features: Precise control over injection volume and pressure to prevent overfilling or underfilling.

6. Final Sealing Station

- Function: Seals the fourth side of the pouch after electrolyte injection.

- Features: Ensures complete hermetic sealing to protect internal components from external contaminants.

7. Formation and Testing Module

- Function: Conducts formation cycles to activate the electrochemical properties of the cell and performs quality tests.

- Tests: Capacity, internal resistance, leakage, swelling, and short-circuit detection.

---

●How Does a Pouch Cell Making Machine Work?

The operation of a pouch cell making machine involves a series of coordinated steps:

1. Material Preparation

- Cathode and anode slurries are prepared and coated onto metal foils.

- Electrodes are cut into precise dimensions based on the desired cell size.

2. Stacking/Winding

- Electrodes and separators are stacked or wound together to form the core assembly.

3. Pouch Insertion

- The electrode assembly is carefully placed inside the aluminum-plastic laminate pouch.

4. Initial Sealing

- Three sides of the pouch are sealed using heat or ultrasonic welding techniques.

5. Electrolyte Injection

- Liquid electrolyte is injected into the pouch through the open side.

6. Final Sealing

- The fourth side of the pouch is sealed to create an airtight enclosure.

7. Formation and Testing

- Cells undergo formation cycles to activate their electrochemical properties and are tested for quality assurance.

---

●Advantages of Using a Pouch Cell Making Machine

1. High Precision:

- Automated systems ensure consistent alignment, stacking, and sealing, reducing defects and improving product quality.

2. Increased Efficiency:

- Automation speeds up production, enabling manufacturers to meet growing demand for pouch cells.

3. Cost Savings:

- Reduces labor costs and minimizes material waste through precise handling and processing.

4. Scalability:

- Can be configured for small-scale prototyping or large-scale mass production, depending on the application.

5. Improved Safety:

- Minimizes human exposure to hazardous materials like electrolytes and ensures safer working conditions.

Battery Production Line

●Challenges in Pouch Cell Making Machines

While pouch cell making machines offer numerous benefits, they also present certain challenges:

1. Complexity:

- The integration of multiple modules requires advanced engineering and software control systems.

2. Swelling Management:

- Ensuring minimal swelling during electrolyte injection and subsequent cycling remains a technical hurdle.

3. Sealing Integrity:

- Achieving reliable seals that withstand repeated charge-discharge cycles is critical but challenging.

4. Maintenance Requirements:

- Regular calibration and maintenance are necessary to maintain optimal performance and avoid downtime.

---

●Innovations in Pouch Cell Making Machines

To address these challenges and enhance productivity, manufacturers are incorporating cutting-edge technologies into pouch cell making machines:

1. Advanced Sensors and Vision Systems:

- Real-time monitoring of electrode alignment, sealing quality, and electrolyte levels ensures consistent output.

2. AI and Machine Learning:

- Predictive analytics optimize machine performance, detect anomalies, and improve yield rates.

3. Modular Design:

- Flexible machine configurations allow easy adaptation to different cell sizes and chemistries.

4. Sustainability Features:

- Eco-friendly designs minimize energy consumption and material waste during production.

---

●Applications of Pouch Cell Making Machines

Pouch cell making machines are widely used across industries requiring lightweight, high-energy-density batteries:

1. Consumer Electronics

- Smartphones, tablets, laptops, and wearables benefit from the compact and customizable nature of pouch cells.

2. Electric Vehicles (EVs)

- Many EV manufacturers rely on pouch cells for their superior energy density and space optimization.

3. Energy Storage Systems

- Residential and commercial energy storage solutions increasingly adopt pouch cells for scalability and efficiency.

4. Aerospace and Defense

- Lightweight pouch cells power drones, satellites, and other aerospace applications demanding high-performance energy storage.

---

●The Future of Pouch Cell Making Machines

As the demand for advanced batteries grows, pouch cell making machines will continue to evolve. Key trends shaping the future include:

1. Integration with Solid-State Technologies:

- Machines will adapt to handle solid-state electrolytes, enabling safer and more efficient next-generation batteries.

2. Higher Throughput:

- Advances in automation and robotics will further boost production speeds without compromising quality.

3. Customization Options:

- Modular designs will allow manufacturers to tailor machines for specific cell types and chemistries.

4. Sustainable Manufacturing:

- Recycling capabilities and eco-friendly processes will become integral parts of future making machines.

---

●Conclusion

Pouch cell making machines are indispensable tools in modern battery manufacturing, driving innovation and efficiency in the production of lightweight, high-performance pouch cells. As advancements in materials science, automation, and sustainability continue to unfold, these machines will play an increasingly important role in shaping the future of energy storage.

What excites you most about the future of pouch cell making machines? Share your thoughts in the comments below! Together, let’s explore how technology can drive a cleaner, more sustainable energy landscape.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com